ELASTOMER MATERIALS FORHOME APPLIANCES

TPE

TPE material is odorless, eco-friendly, non-toxic, and has no impact on human health

Food-grade materials for environmental protection, featuring processing technology superior to silicone rubber

Odorless and stable processing, compliant with FDA food system certification

Resistant to hexane,alcohol, acetic acid, etc

Sports equipment elastic material

TPE

Recyclable, safe and environmentally friendly

Comfortable to the touch, dry and delicate

Folding resistance, excellent toughness, good rebound performance, excellent wear resistance and puncture resistance, longer service life

Waterproof, slip resistant, hydrolysis resistant, sweat acid resistant, UV resistant, high and low temperature resistant, and will not undergo any performance changes after immersion in water or exposure to sunlight

Wheel elastic material

TPE

The encapsulated PP is firm and will not separate or fall off, with excellent wear resistance

Durable and highly elastic, capable of bearing heavy loads, with a dry and dry surface that does not produce oil or slip, ultra quiet, does not damage the floor, and has a long service life

Building sealing elastic material

TPV/TPE

Acid and alkali resistance, aging resistance, corrosion resistance, dust prevention

Good sound insulation, resistant to high and low temperatures

Elastic materials for fast-moving consumer goods

TPE

The surface is dry and does not produce oil

Good rebound and no deformation

Good coloring and rich colors

Excellent anti slip effect, scratch resistant, non-toxic, antibacterial, dry and oil-free surface

Medical and health elastomer materials

TPE

Good stability of extrusion and rolling processes

Stable size, good elasticity, high toughness, good transparency

Resistant to bending and not easily knotted, with good transparency

Absorbent, soft and non slippery hand feel

Elastic material for electric tools

TPE

Can bond firmly with PP, PC, ABS, PA6, PA66, and stainless steel

Comfortable and smooth to the touch, no oil leakage

Surface scratch resistant, scratch free, anti slip and shock-absorbing

Automotive elastomer materials - interior design

TPV/TPE

Low odor, low VOC, low atomization value

Good resilience, not easily bent

The surface is dry and does not produce oil

Scratch resistant, scratch resistant, and aging resistant

Automotive elastomer materials - exterior decoration

TPV

Good mechanical properties, compatible with PP

Excellent temperature resistance up to 125 ° C

Excellent wear and scratch resistance

Good heat aging resistance

Excellent UV resistance: meets SAE J2527 standards

Aging test standard: 2500KJ irradiation energy

Automotive elastomer materials - sealing

TPV

Good mechanical properties

Good sealing performance

Excellent UV resistance performance

Low VOC, low odor, low atomization

Good static/semi dynamic sealing performance and excellent aging resistance

Excellent grip power

Smooth, delicate and dry to the touch

Automotive elastomer materials - chassis

TPV/TPEE

Good blow molding performance, good melt strength to ensure uniform thickness

A good inflation ratio ensures a small blow through ratio, smooth inner and outer surfaces, and uniform wall thickness

Excellent flexural performance and fatigue resistance (fatigue testing>500000 times)

Good resistance to liquid media and new energy

Excellent weather and ozone aging resistance

Excellent long-term high temperature resistance performance (150 ° C~3000H)

Widely used temperature range (-40 ° C-150 ° C)

Good compressive deformation resistance

Excellent weather and grease aging resistance

Automotive elastomer materials - engine peripherals

TPEE

Good blow molding and extrusion processing performance

Good melt strength ensures uniform thickness, smooth inner and outer surfaces, and uniform wall thickness

Excellent weather and aging resistance

Excellent long-term high temperature resistance performance (150 ° C~3000H)

Widely used temperature range (-40 ° C-150 ° C)

Good compressive deformation resistance

Excellent resistance to gasoline, antifreeze and other properties

Automotive elastomer materials - interior design

TPEE

Good stability of extrusion and rolling processes

Stable size, good elasticity, high toughness, good transparency

Resistant to bending and not easily knotted, with good transparency

Absorbent, soft and non slippery hand feel

Functional elastomer material

TPE/TPV

High temperature resistance, low extraction, stain resistance, low dielectric constant, strong insulation

Application areas in the automotive industry

TPU

Weather resistant and wear-resistant

Foggy surface appearance

Halogen-free flame retardant

Meet standards such as GB/T, EN, IEC, etc

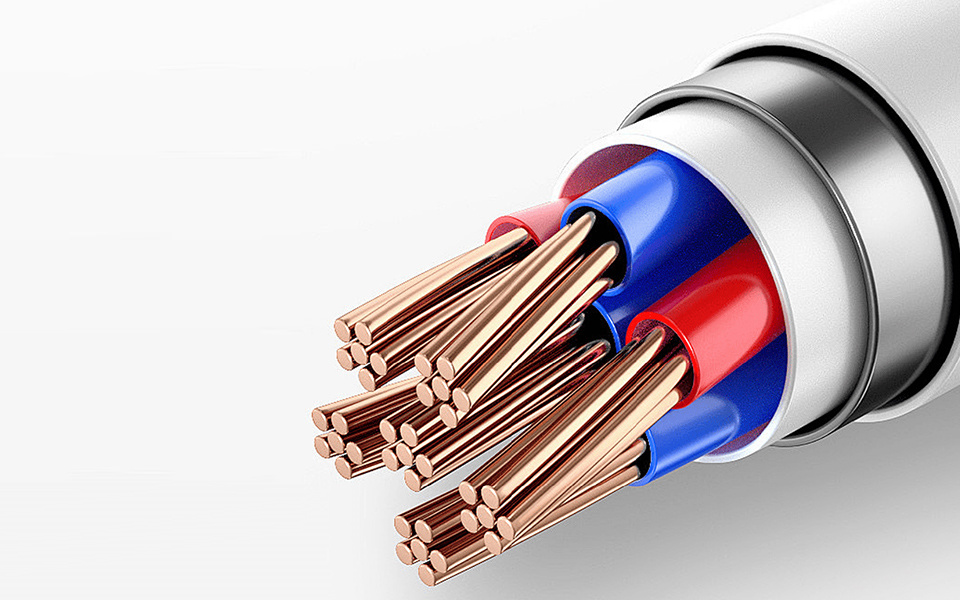

Other industry application areas

TPU

Surface brightness

Good high-speed processing performance

Low fiber attenuation

Other industry application areas

TPU

Foggy surface appearance

High intensity

Aging resistance

Halogen-free flame retardant

Other industry application areas

TPU

Foggy surface appearance

High intensity

Aging resistance

Halogen-free flame retardant

Other industry application areas

TPU

Foggy surface appearance

High intensity

Aging resistance

Halogen-free flame retardant